State-of-the-Art Manufacturing Equipment

Our manufacturing facility spans over 50,000 square feet and is equipped with the latest European and Japanese machinery. We maintain strict quality control at every stage of production to ensure our glass products meet international standards.

Square Feet Facility

Production Capacity

Quality Checked

Precision engineering for superior quality products

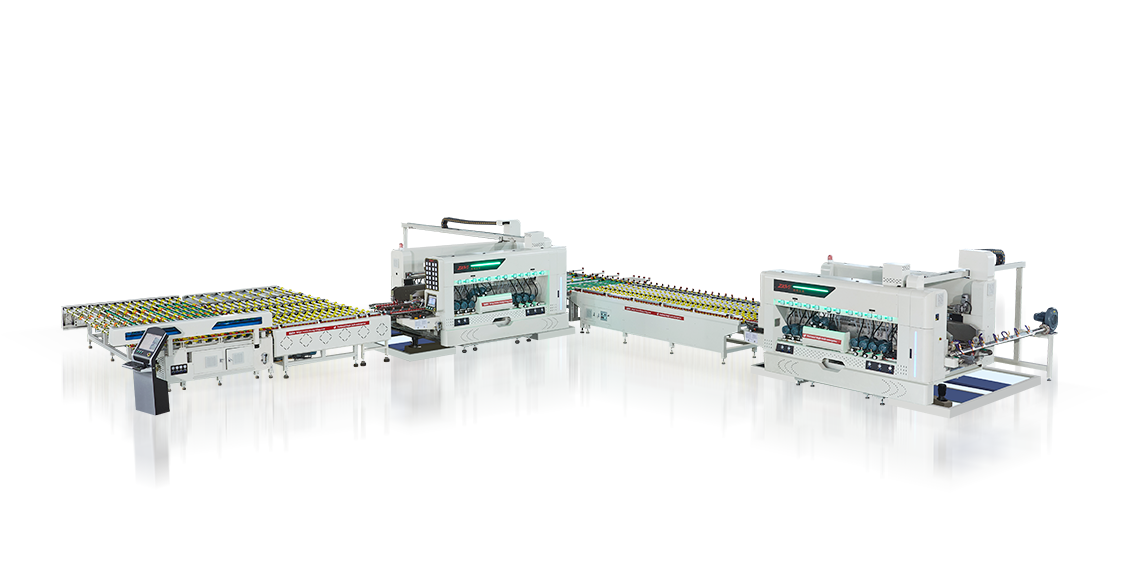

High-precision glass cutting machines with computer-controlled operations for accurate dimensions.

Computer-controlled thermal treatment furnaces for producing high-strength toughened glass.

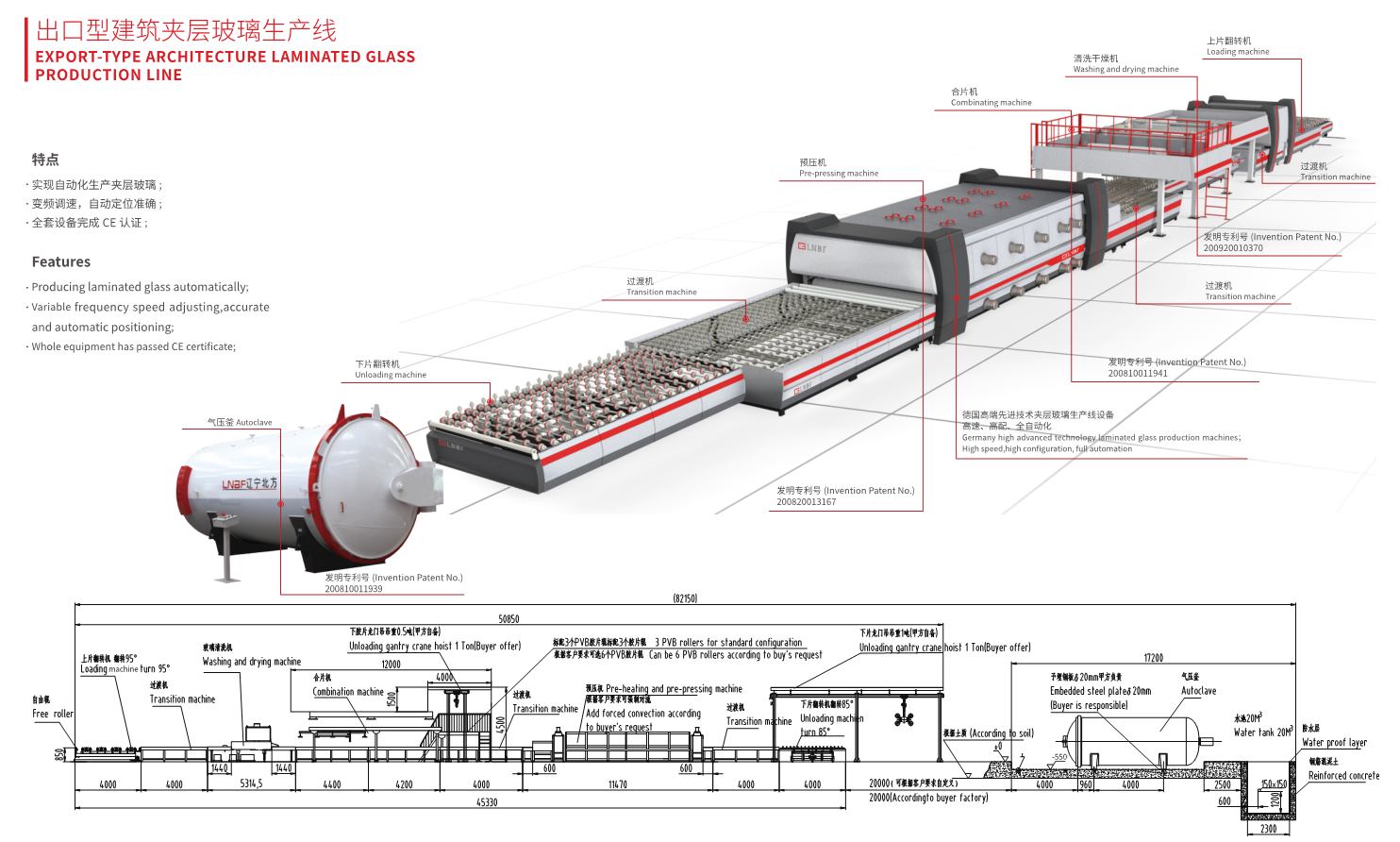

High-pressure autoclaves for bonding multiple glass layers with PVB interlayer.

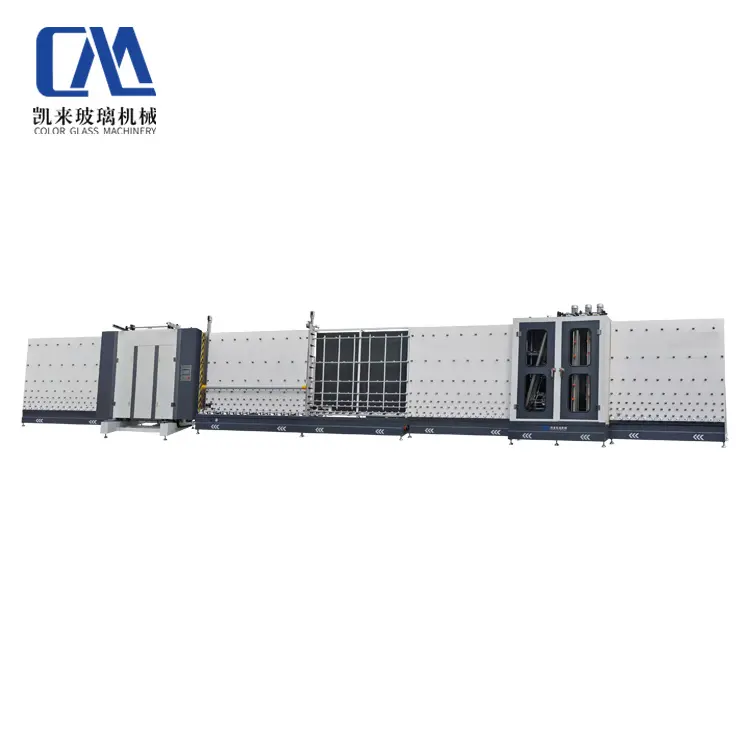

Fully automated line for manufacturing double and triple glazed insulated glass units.

This intelligent double-sided computer edge polish machine delivers high-speed, precision finishing. Utilizing advanced automation and real-time monitoring, it simultaneously polishes both sides of computer components to a flawless mirror finish, ensuring maximum throughput, consistent quality, and exceptional efficiency for mass production..

Constructed with a sturdy steel and aluminum structure.

● Washing and drying section can be lifted for 360mm for easy maintenance.

● NBR conveyor rollers.

● Bevel gears are adopted for steady and synchronous transmission.

Meeting large-scale demands with precision

3250 sqm per day

1950 sqm per day

2800 sqm per day